LOGOS

THE LOGISTICS OPTIMISATION SYSTEM

What is LOGOS?

The movement of goods from the manufacturers to distribution warehouses, retailers, consumers and our own homes, underpins much of modern life and the economy.

Inefficient transport impacts the bottom line and wastes time, fuel, and the environment. For the modern supply chain, reducing these costs and optimising processes are a critical activities.

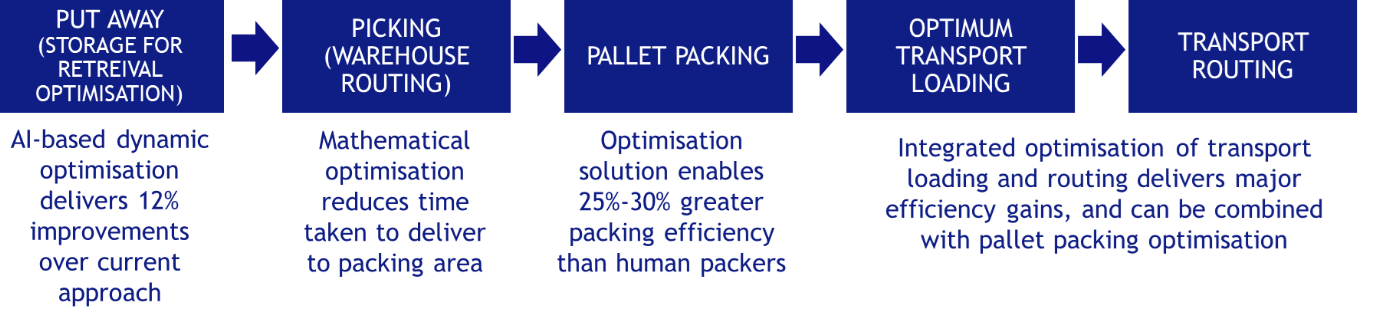

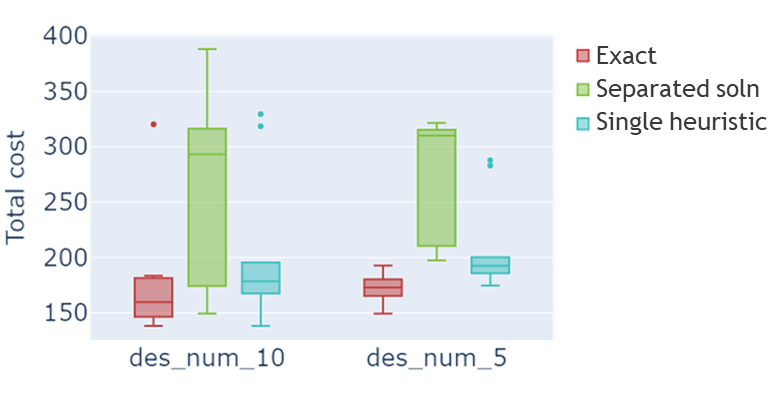

However, processes such as designing warehouse storage, picking, packing and routing are usually computed separately and the benefits of considering the processes together are lost, until now.

Our LOGOS logistics optimisation solution is ideal for dynamic slotting and expands on it, offering high-speed integrated put-away, picking, packing and routing optimisation that breaks through the computation time barrier, offering 15-20% cost savings over present day methods.

What questions LOGOS helps to solve?

LOGOS is a powerful tool that can help you answer key supply chain questions.:

- How can we reduce supply chain operational costs?

- How can we optimise staff allocation at different supply chain points?

- With different, often contradicting, operational objectives, how can I solve all of them at once?

LOGOS combines warehouse and routing optimisation

LOGOS handles a range of objectives and constraints, such as different item sizes, weights, fragility, required orientation, as well as item destinations for multi-drop off loads.

The modular architecture means only the components relevant to your organisational objectives are required, keeping the system streamlined, while new developments can easily be integrated.

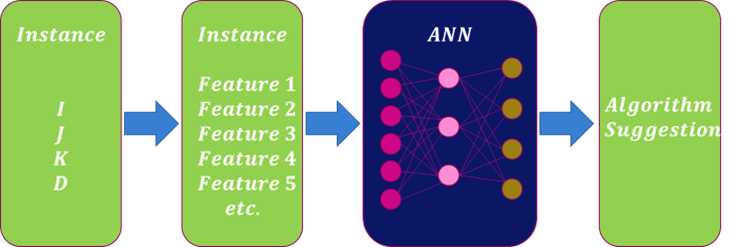

A key feature is the range of cutting-edge algorithms for optimally putting away the items in the warehouse, collecting them, packing them on pallets, and delivering them to multiple end points. But which should you choose? No problem – LOGOS decides using its in-built Artificial Intelligence (AI) to select the best and achieve even better performance.

LOGOS performance

LOGOS can achieve savings of 12% in the put-away process and pack 25-30% more items on a pallet than a human trying to pack different shaped items. It can also save typically 25% savings on transport loading and routing planning compared to the traditional method of doing these separately.

Why LOGOS?

- Major improvement over classical optimisation that separates warehousing from routing

- Proven results with great performance for high complexity large problem sizes within operational timeframes

- A comprehensive solution that can be focussed on specific areas

- Delivers significant savings in costs, time, and space

LOGOS: Optimisation at Speed

Find out more